The Physics of Failure: Data Recovery from Helium-Filled (He) Hard Drives and the Risk of Catastrophic Seal Breach

Introduction

Modern data centers and enterprise storage arrays rely heavily on high-density Hard Disk Drives (HDDs). For years, the industry standard was the traditional air-filled drive. However, the insatiable demand for more capacity led to the invention of the Helium-Filled Hard Drive (He HDD).

He HDDs are technological marvels, pushing storage capacity beyond 10TB and up to 26TB per drive. They achieve this capacity by replacing the internal atmosphere of regular air with the noble gas, helium. But this innovation introduces a catastrophic failure mode that is unique, complex, and presents an existential challenge for data recovery: the seal breach.

When an He HDD seal fails, the data is threatened by physical laws, demanding an immediate, specialized forensic response that goes far beyond standard Cleanroom procedures. For IT managers and cloud engineers, understanding the physics behind this failure is the key to minimizing data loss.

The Physics Behind Helium: A Double-Edged Sword

Helium is not used in hard drives for chemical reasons; it’s used for its physics.

Why Helium? The Advantages of Low Density

Air (which is primarily nitrogen and oxygen) is dense. When the platters inside an air-filled HDD spin at 7200 RPM, the density of the air creates significant drag and turbulence. This drag causes two primary problems: heat and physical instability.

Helium is approximately one-seventh the density of air. Replacing air with helium inside the drive dramatically changes the internal physics:

-

Reduced Drag: The lower density minimizes friction on the spinning platters, allowing them to spin with less energy and generate less heat.

-

Increased Stability: The reduced turbulence allows the read/write heads to fly closer and more stably to the platter surface. This stability allows manufacturers to stack more platters (up to 9 or 10, compared to 5 or 6 in air-filled drives) and use thinner platters, drastically increasing capacity and efficiency.

The Non-Negotiable Requirement: Hermetic Sealing

To maintain this ultra-low-density environment, the He HDD must be hermetically sealed. The case design is fundamentally different from a standard air-filled drive, which has a small vent hole (covered by a filter) to equalize pressure. Helium is contained within a tightly sealed, welded case, ensuring that the light gas does not leak out and that standard, dense air does not leak in.

This hermetic seal is the system’s greatest strength, but also its single catastrophic point of failure.

The Catastrophic Failure Mode: Seal Breach and Air Contamination

The seal on an He HDD is engineered to last, but physical trauma, thermal stress, or manufacturing defects can compromise the case. The moment the seal breaches, the physics that enabled the drive’s high capacity instantly turn against the data.

1. Rapid Pressure Equalization and Contamination

When the seal is compromised, air and atmospheric moisture rush in due to the pressure differential. This immediate contamination creates a toxic internal environment for the sensitive components:

-

Moisture and Corrosion: Atmospheric moisture (humidity) is introduced, posing a severe long-term risk of corrosion to the platters, heads, and internal electronics.

-

Particulate Contamination: Dust, smoke, or microscopic debris in the external environment are sucked into the drive, lodging between the read/write heads and the platter surface.

2. The Head Crash Imperative

The most immediate danger is the massive increase in turbulence and drag. The suddenly dense air dramatically changes the aerodynamic profile the read/write heads are designed to fly on.

-

The heads, calibrated for the frictionless helium environment, now encounter significant resistance.

-

The heads’ flight stability is compromised, causing them to deviate from their path.

-

The gap between the head and the platter (measured in nanometers) is violated, leading to a physical scraping or head crash. This physical contact destroys the magnetic coating of the platter, creating deep scratches and irreversible data loss.

For He HDDs, a seal breach accelerates the failure process from a slow decline into a violent, immediate head crash scenario.

The Recovery Challenge: Beyond Standard Cleanroom Work

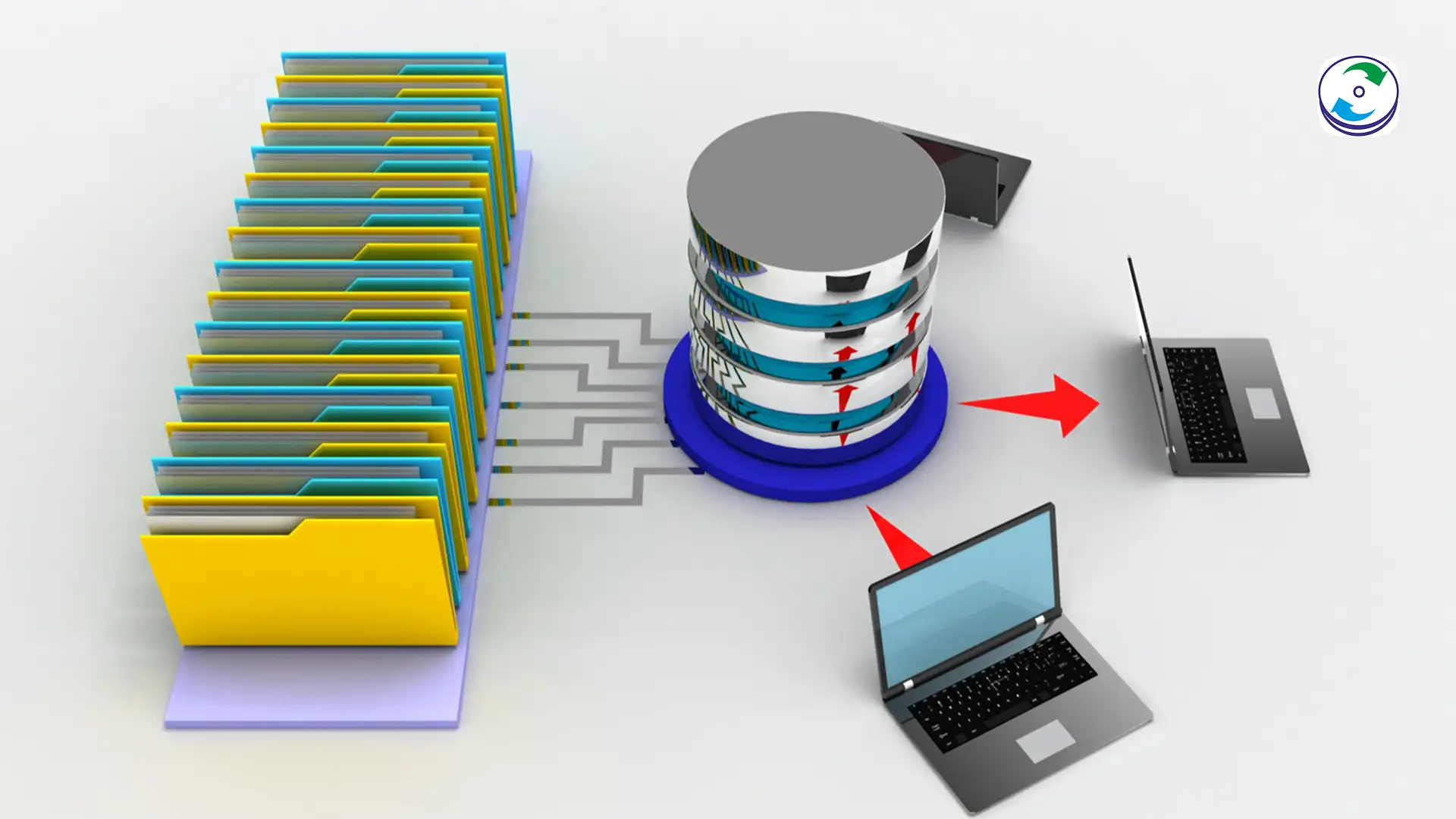

Standard Cleanroom data recovery procedures involve opening the drive in a particle-free environment to replace damaged heads and motors. However, He HDDs pose two distinct, non-standard challenges:

Challenge A: Contamination Control

The internal components of an He HDD are far more sensitive to particulate contamination than air-filled drives due to the higher platter density and tighter tolerances. The introduction of air itself acts as a contaminant. Furthermore, if the drive was exposed to fire, smoke, or corrosive elements after the seal breach, the platters become coated in toxic residue that must be chemically cleaned before they can be spun.

Challenge B: The Helium Vacuum Problem

Once air has replaced the helium, there is no practical way to re-seal the drive with helium in the field or a standard lab setting. The drive must be recovered in a stable, temporary air environment, but this environment must be perfectly clean and controlled to prevent a secondary head crash. The platters—now exposed to air—are still highly susceptible to magnetic damage.

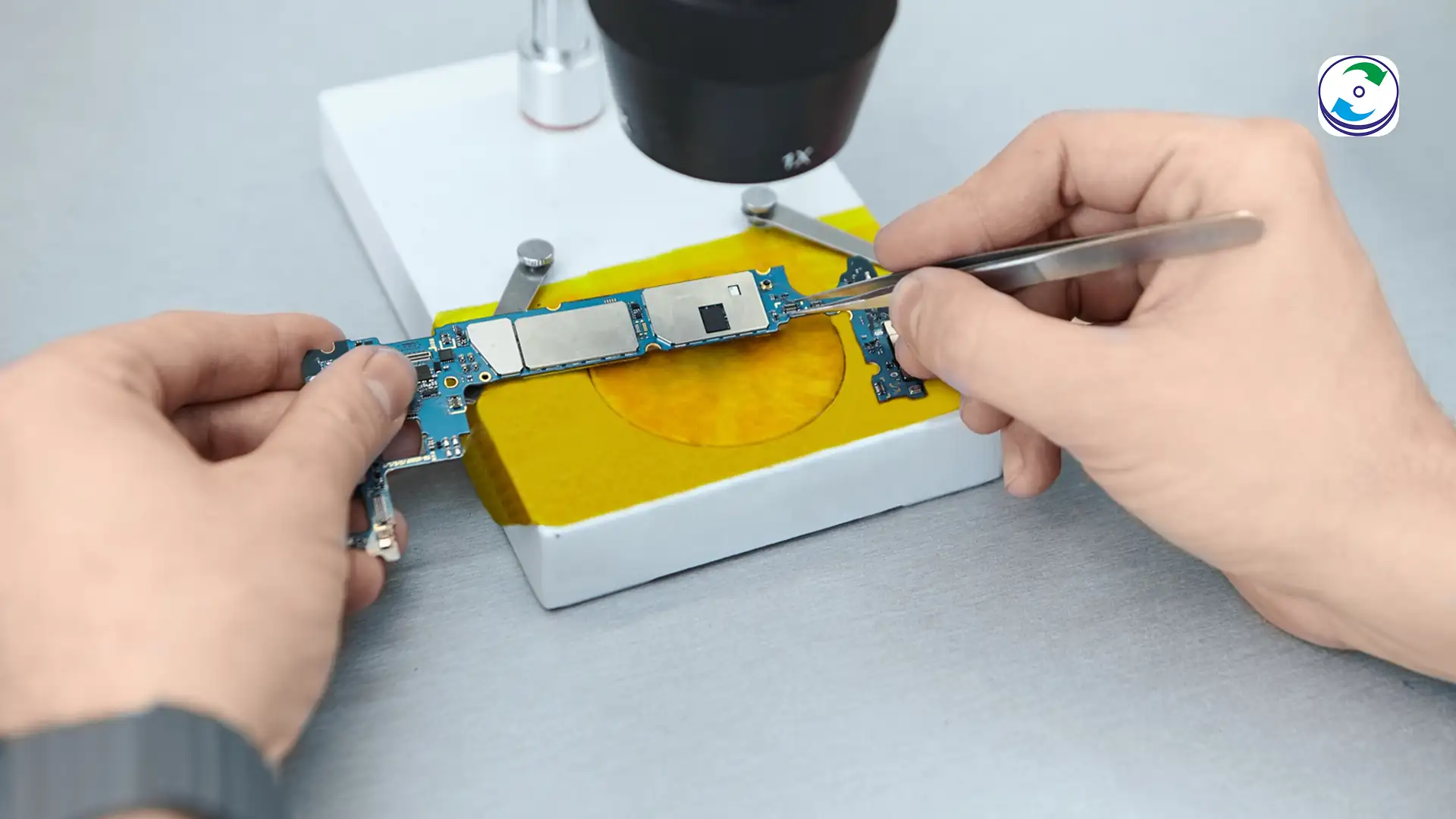

Recovering data from a helium-filled drive requires a protocol built on forensic precision and physics.

-

Immediate Stabilization: The drive is immediately logged and moved to our Class 100 Cleanroom for physical opening. This prevents any further particulate damage from the external environment.

-

Forensic Platter Inspection: Using high-magnification scopes, our engineers inspect the platters for signs of chemical contamination (moisture, smoke residue) and physical scoring caused by the head crash.

-

Component Replacement and Transfer: The damaged read/write head assembly, which often disintegrates upon contamination, is replaced. Because the drive cannot run reliably in air, the platters must be precisely removed and mounted onto a donor air-filled drive (which has compatible hub geometry). This is an extremely delicate process requiring specialized platter alignment tools to ensure the magnetic tracks are preserved.

-

Imaging and Magnetic Stabilization: The platter assembly is spun up in the stable air donor chassis for a single, critical purpose: creating a bit-level image of the data. During this crucial imaging phase, all efforts are made to stabilize the platters against magnetic interference and corruption (e.g., preventing damage from the Curie point if the drive was heat-damaged).

This procedure ensures that the highly dense data tracks—packed closely together due to the drive’s original helium design—are accurately read before the inevitable physical breakdown caused by the dense air environment permanently destroys the data.