Beyond the Cleanroom: How Micro-Soldering Saves Data When the Logic Board is Burnt

Introduction

In the world of data recovery, the dramatic image is often a technician in a Cleanroom, carefully working with spinning platters. However, the most challenging and critical work often happens not with the media itself, but with the drive’s control panel: the Printed Circuit Board (PCB), or logic board.

For an electrically damaged drive—be it a hard drive (HDD) or a Solid State Drive (SSD)—the platters or NAND chips containing your data might be perfectly fine. The failure lies in the PCB, the crucial translator that converts binary data from the platters into a usable language for your computer. When this logic board is burnt, shorted, or water-damaged, the drive is instantly dead.

To recover that data, you need skills that go beyond the Cleanroom: you need the precision of a micro-soldering specialist.

The Data Recovery Limit of the Logic Board

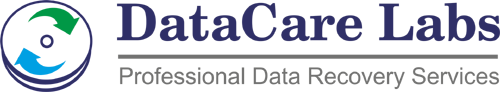

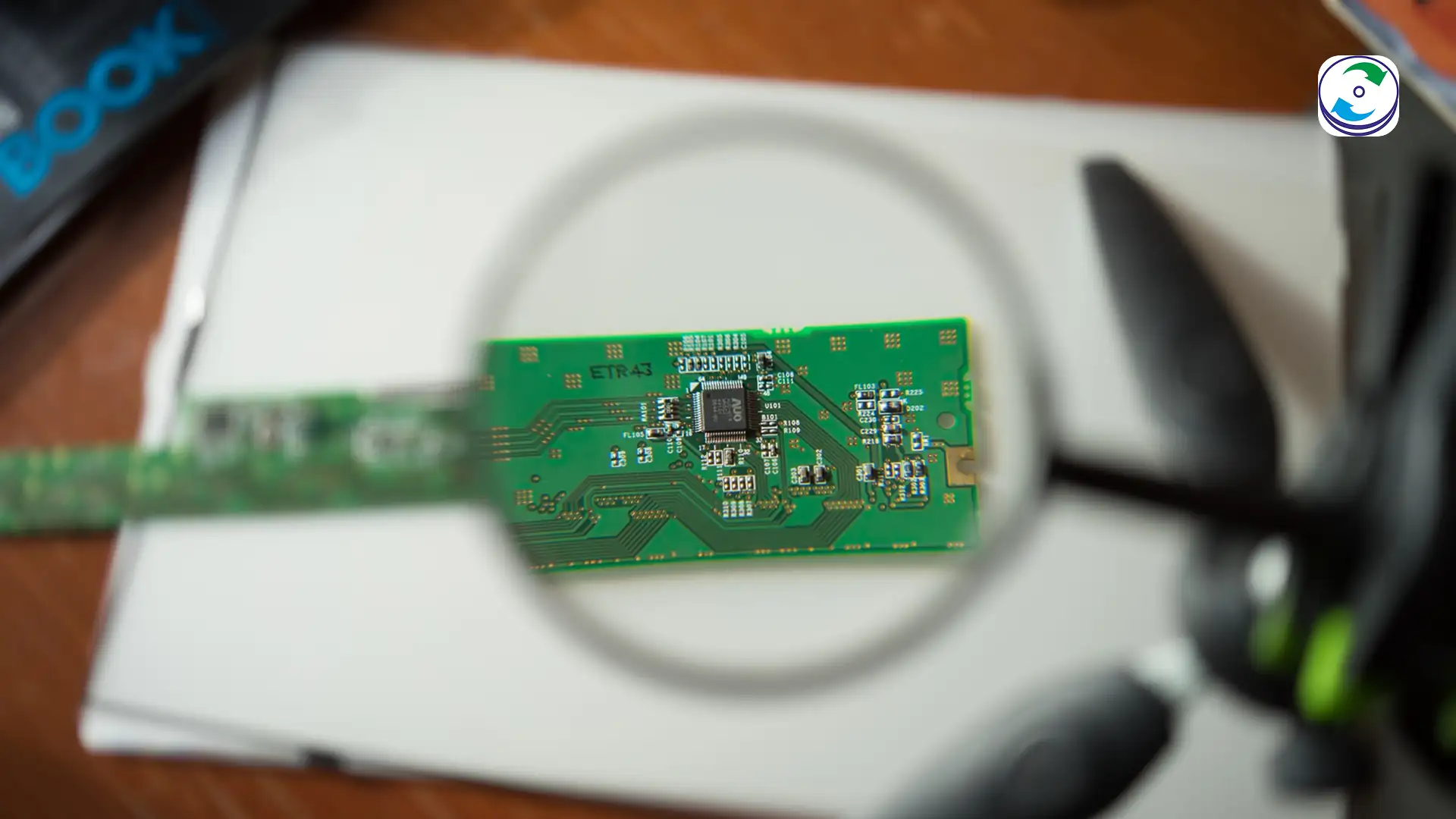

The drive’s PCB is densely packed with components, including the main controller chip, the cache memory, and the crucial Read-Only Memory (ROM) chip. This tiny chip holds the drive’s unique Adaptive Data—the firmware map and calibration settings that tell the read/write heads exactly where to find data on that specific set of platters.

If the PCB fails electrically due to a power surge or liquid damage, the drive cannot power up or communicate. If you simply replace the damaged board with a healthy one from a matching drive (a “donor board”), the drive will almost certainly fail to initialize. Why? Because the ROM chip on the donor board has the wrong map, and the drive’s internal components will not respond to the foreign logic.

When Micro-Soldering is the Only Solution

Micro-soldering is the technique of performing component-level repairs and modifications on electronic circuit boards under high-magnification microscopes. This level of precision is non-negotiable for rescuing data from electrically failed drives.

This elite skill is required in several critical failure scenarios:

-

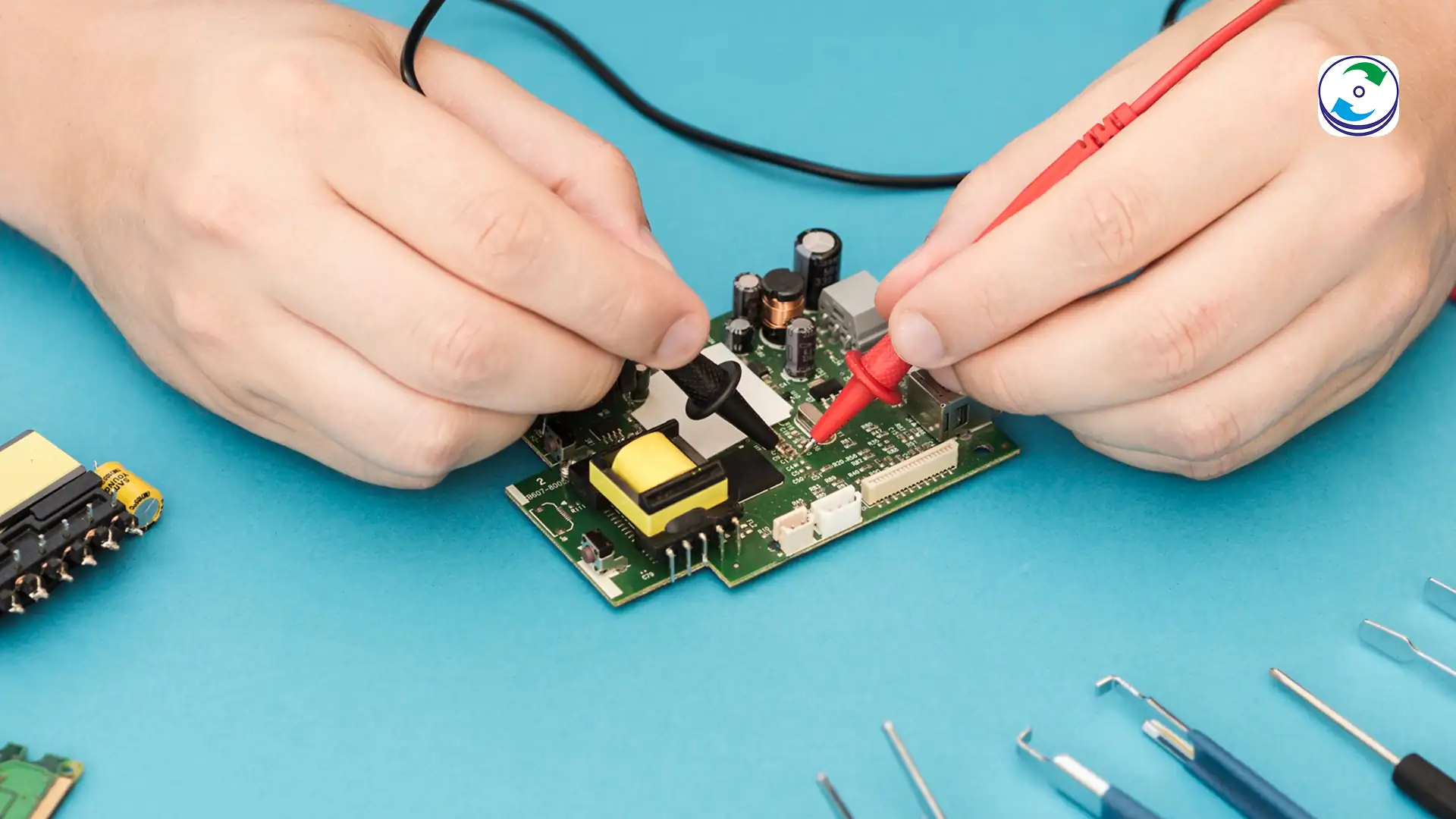

Power Surge Damage: A common failure is a power surge that blows the TVS (Transient Voltage Suppressor) diode. While an experienced technician can replace this blown component, the damage can often extend deeper, requiring the repair or replacement of power regulation circuits.

-

Liquid or Fire Damage: Water or heat causes irreversible short circuits on the PCB. The technician must identify and often replace multiple tiny, surface-mounted components before the board can power on safely.

-

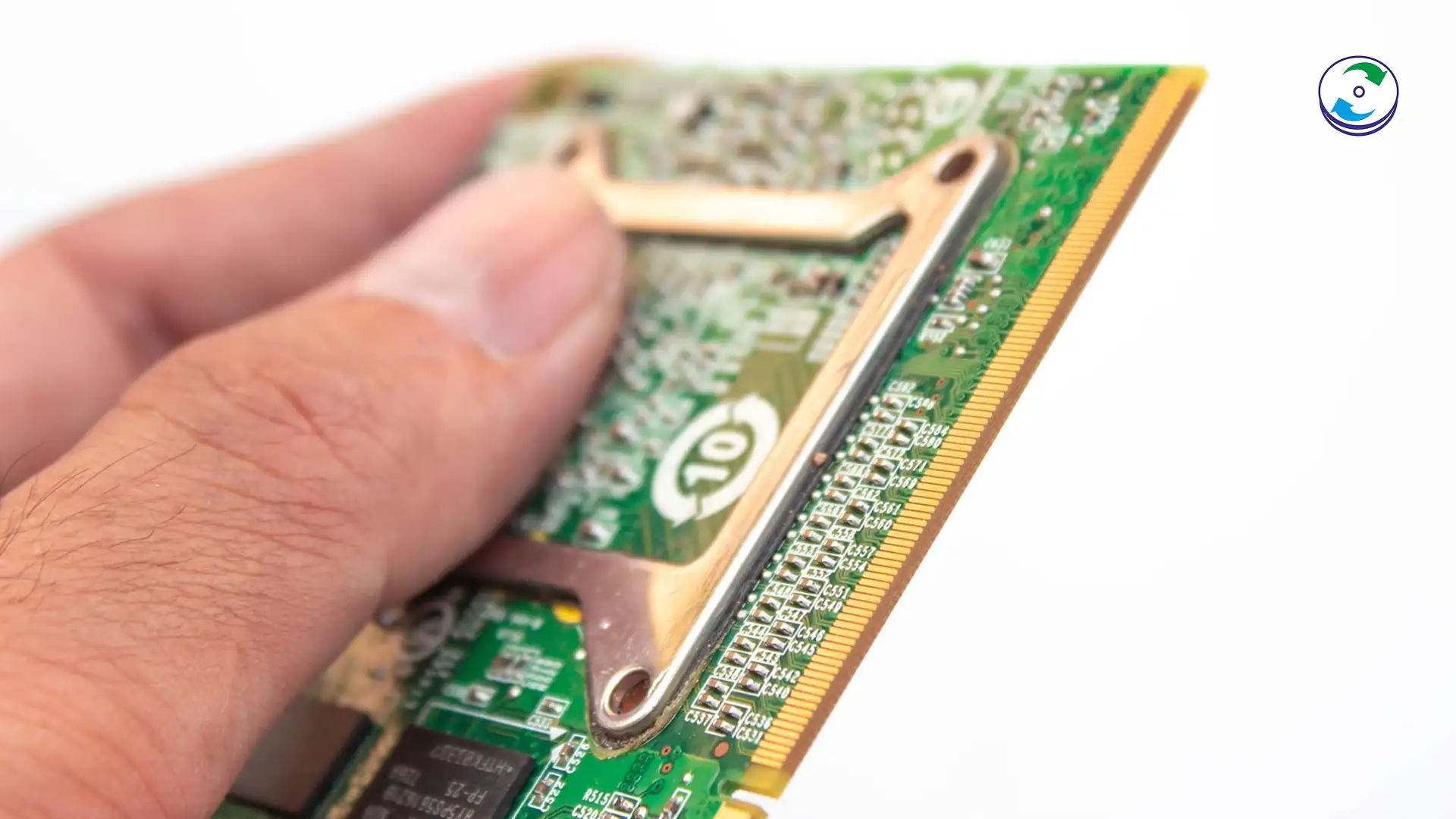

ROM Chip Transfer: This is the most crucial micro-soldering procedure. The original, functional Adaptive Data must be extracted from the ROM chip of the damaged board and transferred to the working donor board.

The Advanced Procedure: Donor Board Swap and ROM Transfer

To bypass a damaged PCB, our engineers perform a procedure that few standard IT shops can attempt:

-

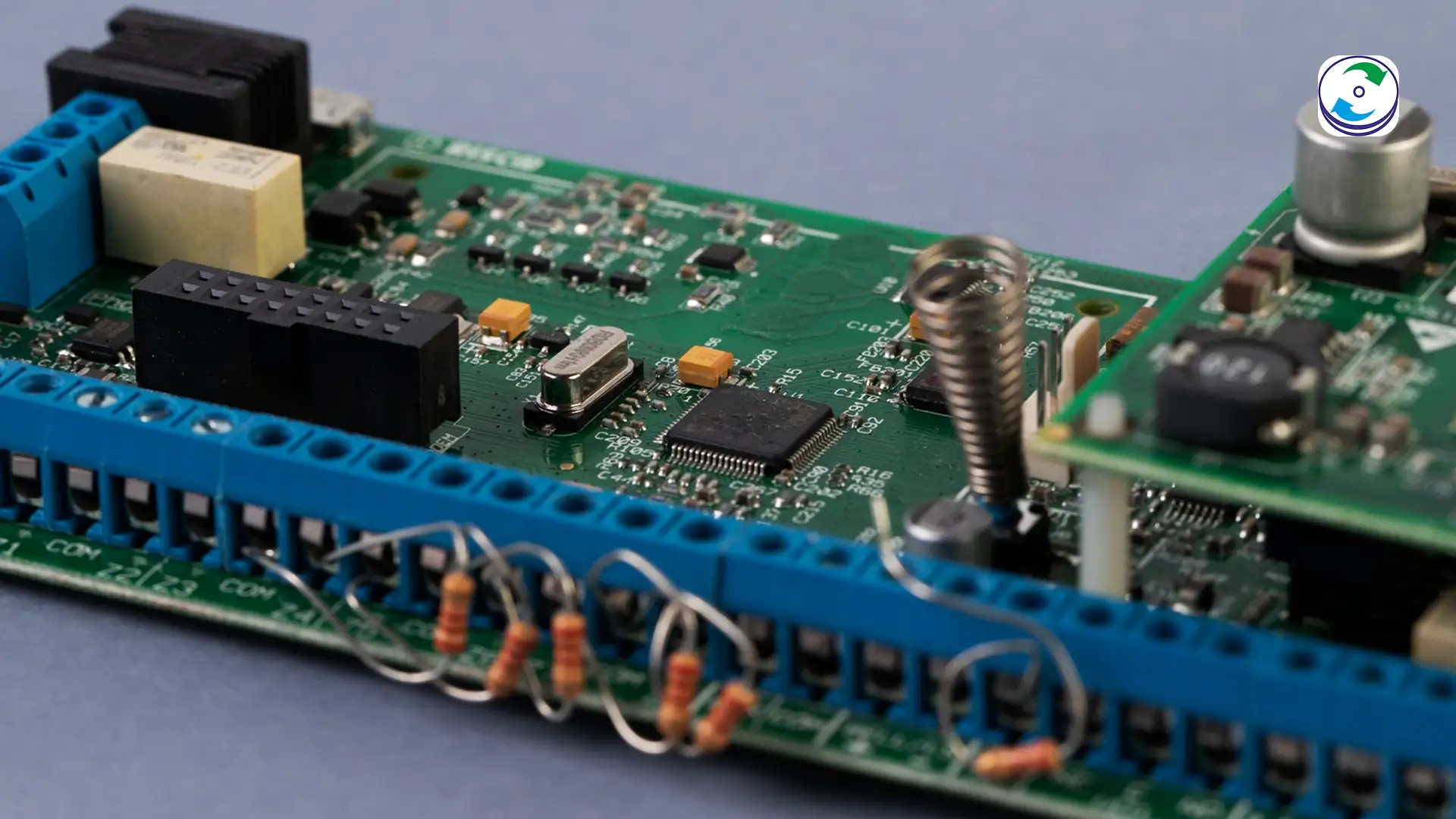

Diagnosis and Donor Match: The drive’s controller and interface chips are checked. A matching donor PCB is sourced—often requiring an exact match of revision and firmware.

-

The ROM Extraction: Using a high-precision hot-air station and microscopes, the tiny, critical ROM chip is delicately de-soldered from the original, failed board.

-

The Re-Soldering: The original ROM chip is then perfectly aligned and re-soldered onto the donor board.

-

Data Access: When the drive is then powered on with the adapted donor board, the correct firmware map is restored. The drive initializes, and the technician can immediately begin the crucial step of cloning the data to a healthy storage device.

Conclusion: Component-Level Expertise Defines a True Lab

The ability to perform component-level micro-soldering is the single greatest factor differentiating a true data recovery lab from a software-based shop. When your hard drive or SSD has suffered an electrical crisis—showing no signs of life, clicking strangely, or smelling burnt—the fate of your data lies in the hands of a technician with a microscope and a soldering iron.

Do not attempt to swap PCBs yourself; without the specialized transfer of the ROM chip, you risk permanent damage. If your media is electrically or physically damaged, partner with the specialists who possess the elite micro-soldering skills to bring your dead drive’s logic back to life. Contact DataCare Labs immediately for expert diagnosis and recovery.