Data Recovery from Embedded Systems in IoT: Extracting Logs and Configuration from Industrial Sensors and Smart Devices

Introduction

The world is increasingly run by embedded systems: tiny, silent computers operating inside everything from smart thermostats to critical industrial control systems (ICS). In the realm of the Industrial Internet of Things (IIoT), these sensors and edge devices are responsible for recording temperature fluctuations, monitoring pressure levels, tracking energy consumption, or controlling factory robotics.

When an industrial sensor or a critical smart device fails—due to a power surge, firmware corruption, or physical damage—the immediate priority shifts from repairing the hardware to recovering the last operational state. This lost information—the internal logs, the specific configuration file, or the proprietary data stream—is vital for post-mortem analysis, diagnosing security breaches, and preventing future infrastructure failures.

However, recovering data from these minimal devices is arguably the most challenging task in the digital forensics world. These devices lack standard hard drives or large SSDs; they rely on minuscule, volatile memory chips, requiring specialists to use surgical and electrical engineering techniques like JTAG/UART access and In-Circuit Programming (ICP) to extract the digital truth.

The Recovery Challenge: Resource-Constrained Memory

The difficulty in recovering data from an embedded system is a direct result of its design philosophy: minimalism for power efficiency and cost reduction.

1. Minimal and Volatile Storage

IoT and IIoT devices use extremely small-capacity storage, often measured in kilobytes or megabytes, not gigabytes.

-

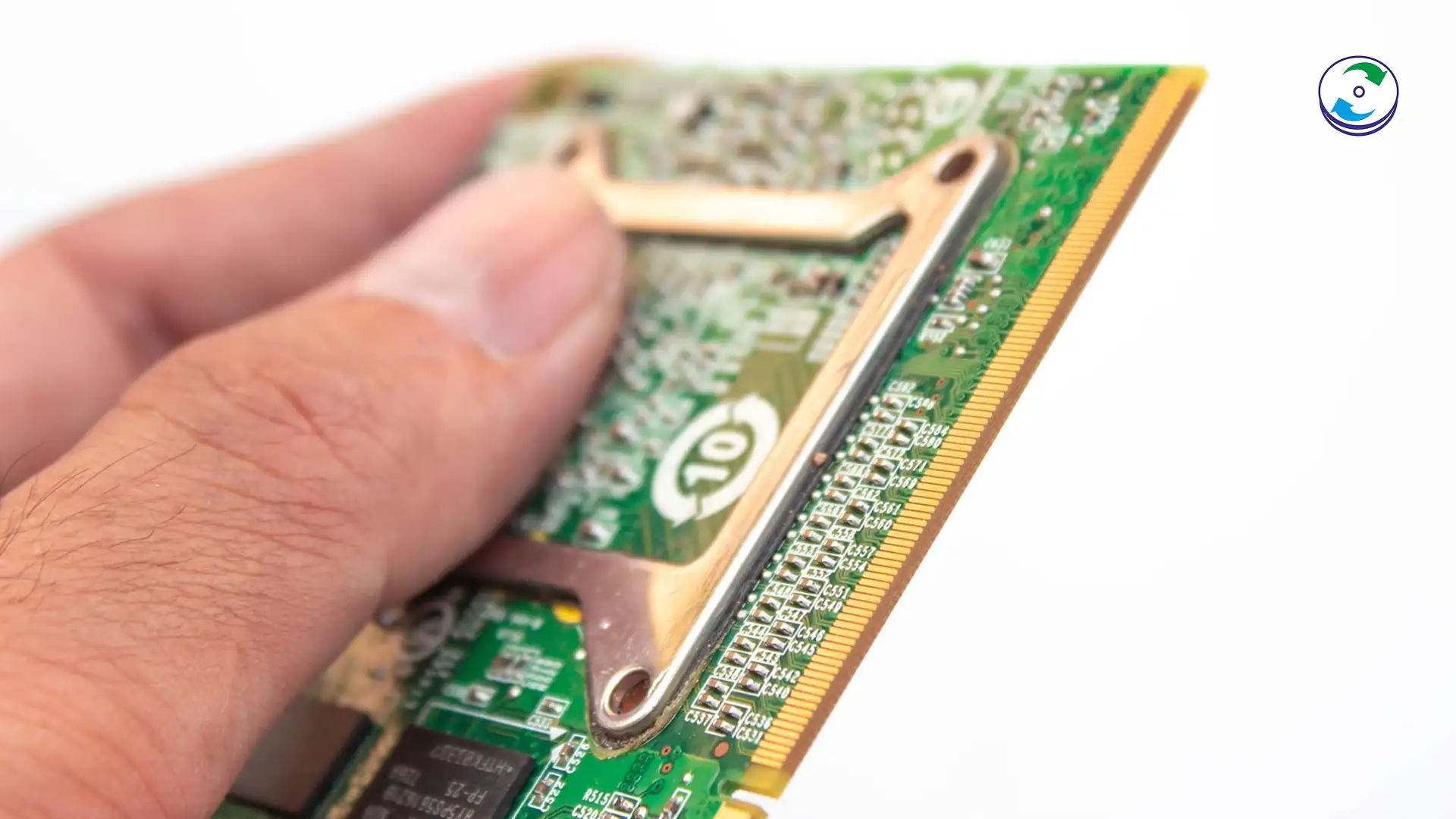

SPI Flash and EEPROM: Data is frequently stored on small SPI (Serial Peripheral Interface) Flash or EEPROM (Electrically Erasable Programmable Read-Only Memory) chips. These chips are usually soldered directly to the main logic board. They are designed for limited write cycles and quick access, making data more susceptible to corruption during a sudden power loss than data on a larger, buffered SSD.

-

The Log Overwrite Problem: Because storage is so limited, many embedded systems utilize a circular logging mechanism, similar to DVRs, but on a much smaller scale. If a device fails during a high-activity period, the critical log entries immediately preceding the failure may be the first to be overwritten, even by the failing device’s own attempts to restart.

2. Non-Standard Communication Interfaces

Embedded systems do not have USB or Ethernet ports designed for data extraction. They rely on low-level electrical interfaces intended for development and debugging.

-

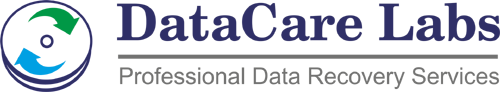

JTAG/UART Ports: Engineers must locate and access the JTAG (Joint Test Action Group) or UART (Universal Asynchronous Receiver-Transmitter) test points. These are tiny clusters of metallic pads or pin headers on the PCB, often hidden or unmarked. These ports are the only non-destructive way to communicate directly with the device’s main microcontroller or processor.

-

Proprietary Firmware: The data is usually stored using a custom, proprietary file structure defined by the device’s unique, resource-constrained real-time operating system (RTOS), making standard file system parsing impossible.

The Forensic Solution: Electrical Engineering Meets Digital Forensics

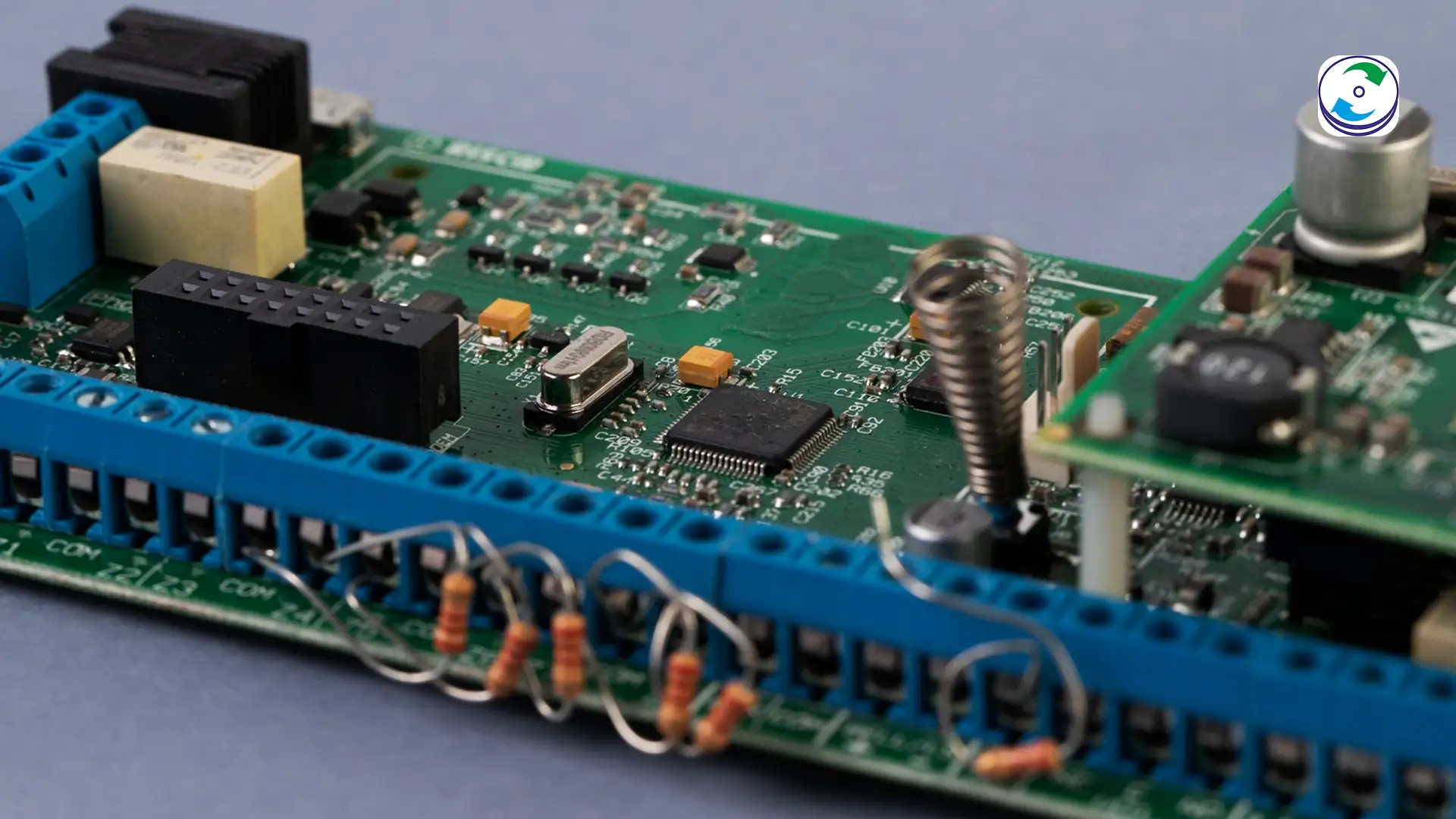

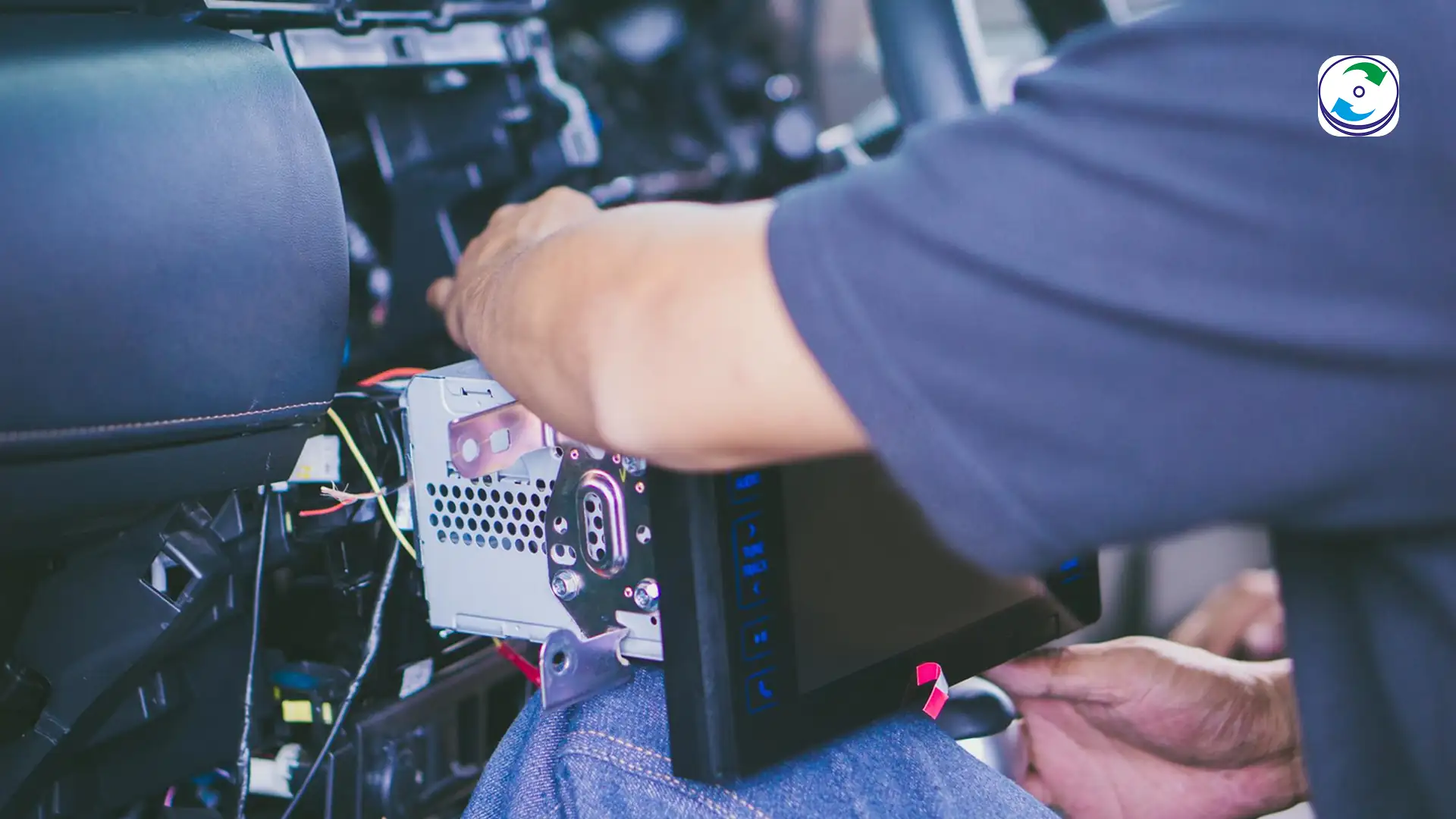

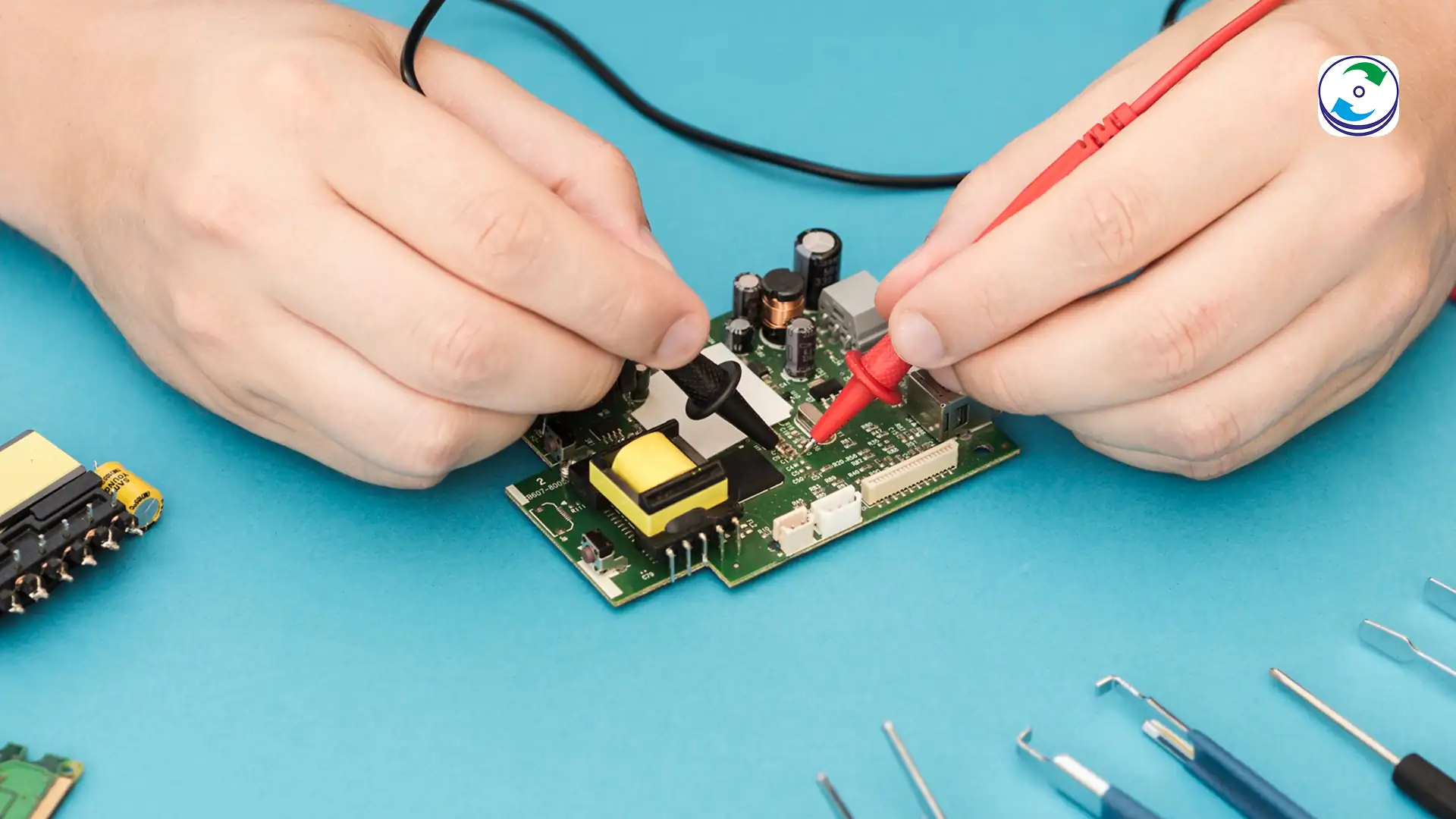

When an industrial sensor fails, accessing the data requires forensic specialists to become electrical engineers, using custom jigs and delicate soldering to bypass the normal operation of the device.

Method 1: In-Circuit Programming (ICP)

This technique is used when the memory chip is intact but the device’s main processor is damaged or uncommunicative.

-

Direct Communication: The forensic team locates the specific SPI/I2C pins on the logic board that connect directly to the memory chip.

-

Specialized Clamp/Clip: A specialized IC clip or programming clamp is attached to the memory chip while it is still soldered to the board. This clamp acts as a temporary connector, allowing an external memory programmer to read the chip’s contents.

-

Bypassing the Processor: By directly controlling the chip’s power and communication lines, the external programmer can extract a bit-level image of the memory, entirely bypassing the failed or corrupted main processor. This is a non-destructive way to capture the raw data without physical chip removal.

Method 2: JTAG/UART Forensic Access

When the device’s processor is functional but locked or firmware-corrupted, JTAG/UART provides a deeper access channel.

-

Pinout Identification: Engineers use schematics or microscopic analysis to locate the often-unmarked JTAG or UART test points.

-

Micro-Soldering: Ultra-fine wires are micro-soldered to these minuscule pads to establish a connection.

-

Debug Console Access: Through the UART port, the specialist can access the device’s serial debug console. This allows them to issue commands to the device’s bootloader or firmware to dump the contents of the memory to an external computer. JTAG, offering an even deeper connection, allows for boundary-scan testing and direct manipulation of the device’s internal registers and memory areas. The technical capabilities of JTAG are widely utilized in firmware security research, as detailed in specialized literature on JTAG port exploitation.

Method 3: Chip-Off for Physically Destroyed Devices

In cases of catastrophic physical damage (e.g., a crushed sensor or liquid immersion), the Chip-Off procedure is the only option.

-

Surgical Removal: The tiny SPI/EEPROM chip is carefully de-soldered from the PCB using thermal equipment.

-

Custom Jig/Adapter: Due to their non-standard sizes, these chips are placed into custom-made, specialized adapters (often requiring custom pin mapping) to fit into a universal memory reader.

-

Raw Data Decryption: The raw data dump is then analyzed to reconstruct the proprietary file system, extract the non-volatile configuration parameters, and, crucially, identify the embedded encryption keys used to protect the operational logs.

Conclusion: The Unspoken Value of Embedded Logs

The configuration files and operational logs stored within an IIoT sensor or embedded system are often the most critical data an organization possesses when facing an infrastructure failure or a breach. Without them, diagnosing the root cause of an outage, or conclusively proving a security vulnerability, becomes impossible.

Standard recovery methods fail against the minute memory chips, proprietary firmware, and non-standard interfaces of these devices. Accessing this data requires a blend of high-precision electrical engineering and cutting-edge digital forensics, utilizing tools like JTAG/UART and In-Circuit Programming.

If your industrial or smart infrastructure has suffered a loss and the critical logs are trapped inside a failed embedded system, do not attempt unauthorized soldering or basic recovery. Contact DataCare Labs immediately to deploy our specialized protocol for embedded system forensics and retrieve the vital operational history of your IoT devices.